STOUGHTON, MASSACHUSETTS, UNITED STATES, February 21, 2022 /EINPresswire.com/ -- Nowadays, green hydrogen is becoming the focus of global renewable energy industry. By the end of 2020, there were about 70 green hydrogen projects under construction around the world, including more than 20 GW-level projects. Last year, Europe released a milestone strategy to support the development of green hydrogen, proposed a development goal of building 6GW

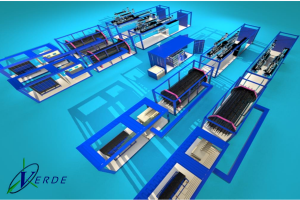

of electrolytic green hydrogen capacity by 2024 and nearly 40GW of electrolytic green hydrogen capacity by 2030.The emergence of 2.5MW Containerized single-stack hydrogen production system from the Angstrom Group has contributed to the development and popularization of green hydrogen. This system adopts advanced alkaline water electrolysis hydrogen production patented technology, the total footprint only occupies 2 of 40ft containers (1 40ft and 2 20ft), saving land resources, and the system can be modularized to 10MW/100MW or even larger module scales. The system comes with a 500Nm3/h hydrogen capacity, purity can reach 99.999% after purification, and the maximum output pressure is 1.6MPa. The entire system only takes about 2-3 weeks to be installed, which is 80% less than traditional hydrogen plants, much reducing the initial investment and labor cost. Moreover, the unique modular design with fully automatic control ensures lower energy consumption, optimized intelligence and integration, and higher safety factor compared with traditional hydrogen production equipment/system, also ensuring the products can work in a variety of harsh and unstable environments.

The successful development and production of the Angstrom 2.5MW Containerized single-stack green hydrogen production System is the result of the combination of the US leading both the technological progress and industrial development trend; it is also a breakthrough in promoting the development of the global hydrogen energy industry.

No comments:

Post a Comment